In the dynamic world of 3D printing, professional plastic printing companies stand out for their incredible work. They use state-of-the-art technology, choose the right materials, and have innovative designers putting them at the forefront of the competition. In this article, we’ll discuss what distinguishes these companies from the rest.

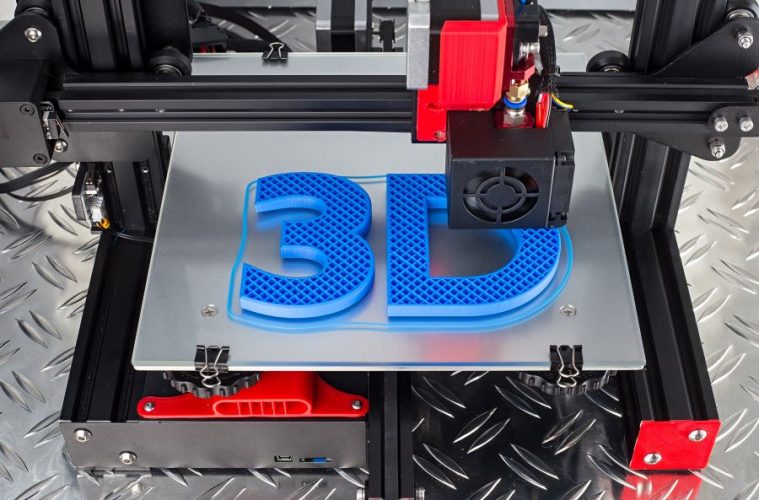

Advanced Technology

At the heart of every professional printing company, there is a commitment to using cutting-edge technology. State-of-the-art 3D printers are fully equipped with the latest advancements to bring imagination to life.

Material Selection and Expertise

Choosing the right material is extremely important in 3D printing. Professional plastic printing companies excel in this aspect of their work by understanding the characteristics of various plastics and choosing the one that is most suitable for the project. With their knowledge and experience in designing products with certain materials, material selection can determine the quality of the product. Whether it’s ABS for its strength or PLA for its ease of use, professional plastic printing companies know which will produce the best results.

Design and Engineering

Behind every successful 3D print is a well-thought-out design and engineering process. Professional plastic printing companies employ skilled designers and engineers who use computer-aided design (CAD) software to create digital models of the product. They then optimise these models for 3D printing to make sure they’re both visually appealing and structurally sound.

Industry Experience

To be established as a professional plastic printing company, there will most likely be years of experience under their belt. The company will have overcome a variety of challenges which has led to processes being improved to deliver consistent high-quality results. From understanding the capabilities of different 3D printers to understanding the complex material properties, these companies have a wealth of knowledge that sets them apart.

Innovation and Adaptability

Innovation is the driving force behind the success of a professional plastic printing company. Companies are consistently exploring new materials, refining printing techniques, and embracing emerging technologies to push the boundaries of what’s possible. Whether it’s experimenting with biodegradable plastics or adopting novel printing methods, they’re always on the lookout for ways to innovate and improve to get ahead of the competition.

Quality Control and Assurance

In professional plastic printing, quality control and assurance systems are important for ensuring consistent results. Companies usually have automated inspection tools and real-time monitoring to detect and rectify any issues during the printing process. Advanced analytics software also provides insights into the process and performance which means continuous improvement.

Customisation and Client Collaboration

Professional plastic printing thrives on collaboration and customisation. It all starts with an in-depth consultation with the client to find out exactly what they’re looking for and to refine the designs. Prototyping and testing allow clients to confirm the design or request any adjustments. Continuous communication ensures the client’s needs are met, driving innovation and satisfaction.

Advantages of 3D Printing over Traditional Moulding

3D printing surpasses plastic injection moulding in many ways. It lets you create detailed designs and intricate shapes without limits, giving you more freedom in what you can make. Unlike plastic moulding companies, you don’t need expensive tools, so it’s cheaper to get started. This makes it great for making a small number of things quickly or testing out new ideas.

In summary, plastic printing companies are pushing the boundaries of what’s possible in 3D printing. From high-precision printers to versatile materials, these technological innovations enable these companies to deliver great results.